Where it all began!!!

I wanted a new track car, after having a hybrid turbo Megane 250, I found it not very engaging on track and very easy to drive. Looking back to my days in my 106 GTI on throttle bodies, I wanted to build something raw and back to basics. The idea was simple, start with a 5k budget to buy and build a usable track car. I saw some r53 minis online making 220ish hp on the supercharger so this was the plan!

I browsed facebook and found a decent spec R53 being sold by a guy in Birmingham. After a few messages etc i agreed on a price and booked tickets up to collect it. It was a good spec with AP 345mm calipers, cam, reduced pulley, injectors, r56 rear arms, miltek cat back, new clutch and chain kit, caged with buckets and sticky tyres. It needed tidying up etc but was a good base for a car, even though it did nearly take up the whole 5k budget!!

After the drive home I was impressed, it was much more raw than the megane and the steering input was brilliant. I drove it around for a few days but I still had the megane on the drive. I kept going back to the megane due to the fact the mini felt very slow in comparison, having a 160hp deficit on the Meg. After a few more days I decided the mini wasnt for me. Unsure on the next step I put the mini up for sale and a good friend purchased it who was looking to get into track days. The deal was done and he collected it. Hes totally tranformed this car into an epic little machine. We will touch more on this later on!!

Next up was deciding what to do with regards to a track car. I decided to get the megane gone so I could decide on the next steps, as having it looming I figured id always go back to it.

A few days later the megane sold. I kept my corbeau seats and had a few sets of wheels to shift.

Once the Megane was gone I decided to start a R53 turbo project. After searching online I found a few diy builds, and a company 1320 that offer a package for around 13k to turbo a stock R53. Obviousy that was above my budget so i did not consider this at all. I started looking online for information on whats needed to convert these to turbo, and there is literally no information online. Theres a few threads on facebook, mainly on the R53 owners club, but even these are few and far between and lack alot of important information. I found this photo online which took me back to my 1.8turbo days, even using the VAG coils and the resembalance of the BAM pipework. I decided this would be the inspiration!! The turbo location looked better to me than the other sidewinder minis I had seen. Sidewinders do not appeal to me, just seem to move the turbo further into the bay creating even more heat which seems backwards.

I was offered a cheap mini for £500 that had been sat for around 3 years. It was not in great condition, with no history, didnt run overly well and was relitively stock bar a direnza exhuast and a few JCW carbon parts, being the gearknob and handbrake handle. I got a friend to collect the Mini for me and it actually arrived a day before the Megane went.

What a stunner!!

First thing was to see if it actually ran. We jumped it with a starter pack and drove it round the block. The power steering did not work, neither did many lights. Every warning light on the dash was on and as soon as you took the jump pack off it died. What an absolute peach!!

The next day we got it up on stands where the build could start. The idea was to strip it back to basically a shell, service the engine then figure out the turbo parts.

Once up on stands I could inspect the car, not much was salvageable in my opinion. It needed all new suspension, all the brakes were rotten and rusty, all the brake pipes were corroded etc. Every bush looked shot, including the engine mounts and dogbone mount. The boot was also rusted through and i could fit my fingers through the holes!!! Common issue on these ive now come to realise.

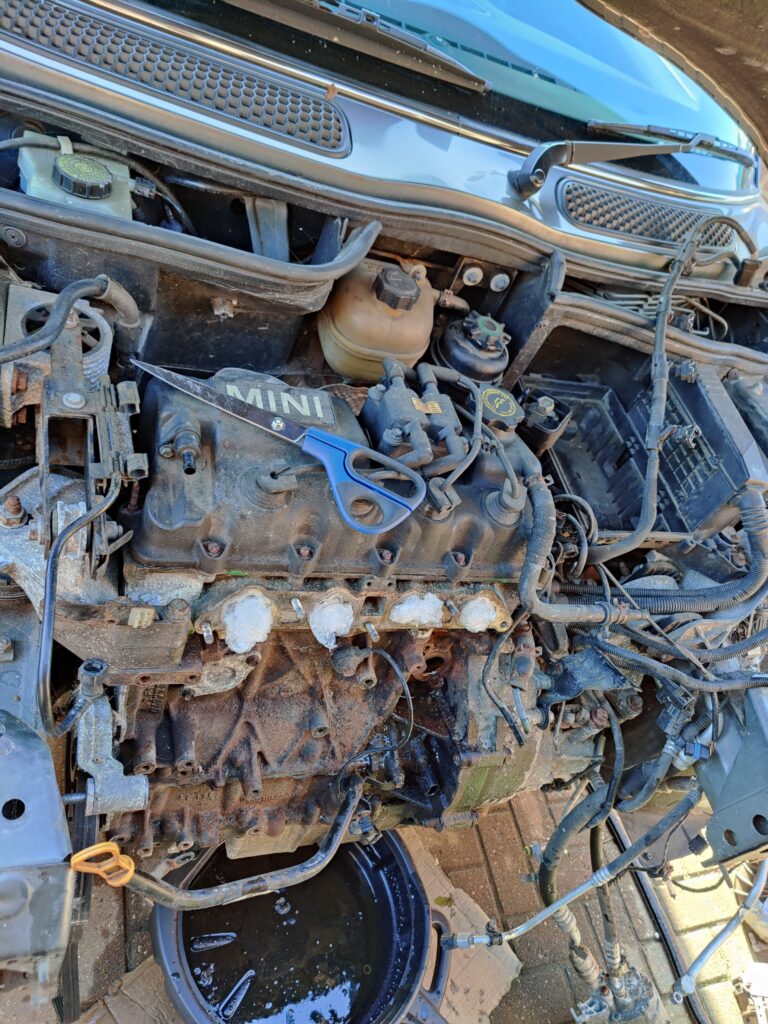

Once up on stands the work could start. I began stripping the engine bay down, removing the charger, all the auxillary setup, water pump, inlet and the ecu box etc. Draining out the fluids it was clear the engine hadnt been looked after overly well in its previous life. Lots of parts were missing and/or broken, including all the vac lines to the charger, clutch pipe was damaged etc etc. There also appeared to have been a mouse or some small animal living in the air filter box at some point!!

A few more pics to show you the actual state of this car. I couldnt find one part that was reusable apart from maybe the shafts!!

After stripping the car down to what was now basically a shell I managed to shift many parts that were not needed, incuding the direnza cat back, supercharger, wheels, front JCW brakes, JCW handbrake and gearknob. After these sold i actually ended up in profit by about £500, so the car had now made me money!! Result, more money for the build.

The next parts on the list were to figure out the AUX setup for the turbo conversion. After reading online it appeared you can use the R50 setup, including alternator, tensioner, water pump and/or air con pump. There are two types of r50 alternator. You need the one with the metal backing instead of the plastic. We decided to ditch the air con as its mainly a track toy. I sourced these parts from a local breaker to keep the cost down and purchased a new belt. There are some small other parts you need for this part. The block has two water feeds on the front. The stock engine when supercharged has the blank plate on the left side. This needs to be moved to the right side with the left side connecting to the water pump using the part from the r50 cooper. You also need a cooper dipstick and the water pipe from the thermostat to the water pump.

Once this was completed the auxillery setup was complete and should work! unfortunately I cannot find any photos of these steps but a simple r50 auxillery setup is whats needed.

A few days later an engine came up on facebook with a 6 paddle clutch and lsd box attached. It also boasted an oil cooler and a ported head. The engine had a few upgrades with the Newman P2 cam, MSD coilpacks and arp bolts throughout prety much. I decided to go ahead with the purchase and a few days later it arrived on a questionable pallet.

At this point I also did some DIY poly engine mounts. Alot of the track guys do this mod, its cheap and effective and better than the powerflex equivilent etc. Simply drill lots of holes in the stock mount, then tape up the edges of one side of the mount and pour the mixed poly. The result is basically a solid engine mount, these come in shore hardness when you order the pourable poly. I went for 80 shore hardness which is probably the same as purple powerflex from experience, but without the price. I did my mounts and a friends and still have a little left, all for the price of £18!!

Started buying parts!! found many facebook and ebay bargains this week. Got a custom inlet manifold from Dave Mills on the R53 owners club, a Quaife ATB LSD in a gearbox for £500, some harnesses for £100 and some HSD monopros in great condition for £500. It was at this point I realised the budget of 5k would not likely stretch, as I had already purchased parts I didnt really need, ie a diff and the fancy manifold.

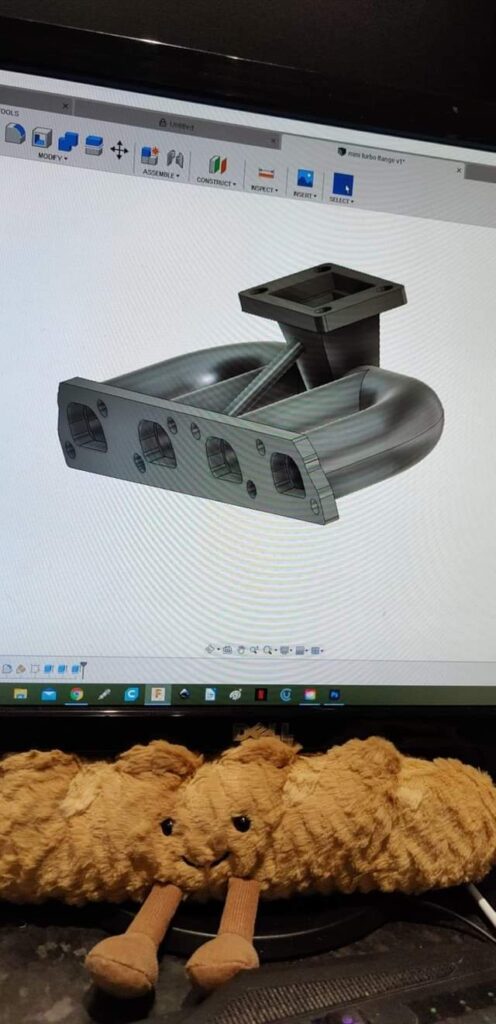

Next up was to get the engine in after giving the bay a little clean and designing the exhaust manifold for the turbo. I fired up CAD and started measuring up where the turbo would sit. (This turned out to be a waste of time and money as I ended up dirtching the manifold to have the turbo in a better location)

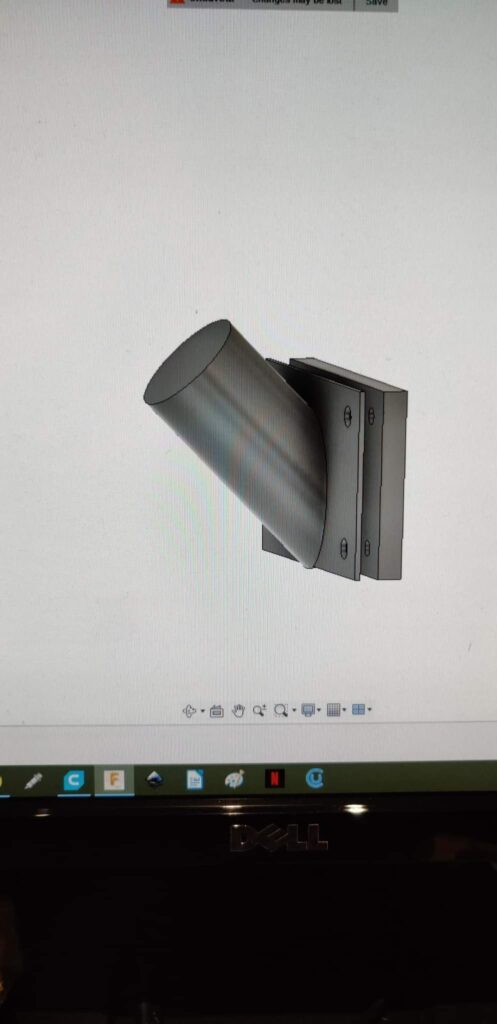

I went with a Pulsar GTX2867r turbo. After checking out the reviews they seemed to be good for the money, which turned out to be around 1/3 of the price of a genuine garrett. The quality looked good when it arrived, and seller was helpful with dispatch info etc. I printed the manifold flanges to check fitment and it appeared the the turbo would fit well leaving a smal gap by the bulkhead. Note in the photos you need to remove the rear plastics that normally cover the brake lines, this allows room for the turbo and manifold.

Soon after we got the engine in. This was easy as the whole subframe etc had been removed so nothing in the way. We attached the gearbox with the Quaife LSD in prior to fitting. Once the engine was in we figued out the coolant and oil feeds for the turbo. This was relitvely easy, we used a stock mini T piece with 19/19/8mm outlets. We spliced coolant hoses and put one in each pipe to the heater matrix. Some high temp hose protection and some banjo fittings for the turbo end. On the oil side I purchased a oil fitting extension which had a T piece on. This simply threaded into the stock oil presure sensor with a 50cm take off. This was p clipped to the block and an aftermarket oil pressure sensor fitted for the aftermarket ECU, along with a braided oil feed for the turbo from HEL performace. The turbo return we will come to later, this will need to be weled to the sump using an AN fitting. Likely to the front of the sump as the angle is odd meaning highest point is at the front.

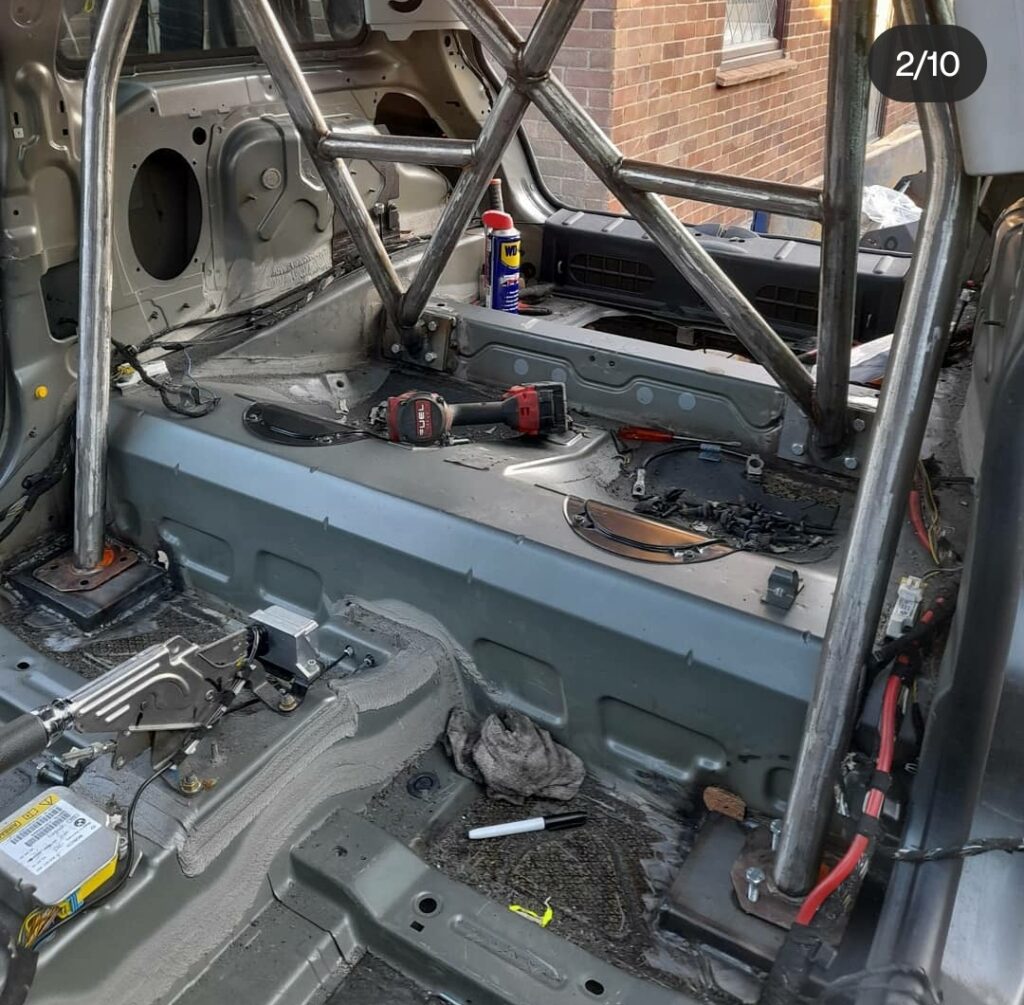

After the engine and oil/water feeds were sorted, I moved onto the interior. This was fully stripped to a shell bar the dash. All door cards were removed, spot welds for the rear seat mounts removed and wiring all tidied in cable trunking. This allowed us room to get the cage put in to figure out how to mount it.

I found a cage on facebook for £300. It didnt come with the feet plates to weld in so I designed my own. Ordered the metal at the lazer cutters and had my guy bend it up and weld the captive nuts in behind. Also made the plates for the front legs as it was too far away from the ceiling for my liking.

Once this was sorted my fab guy came down for the afternoon and welded the feet plates into the car. Cage fit was perfect!! Much safer than what how it was supposed to be mounted to the isofix brackets.

Next up was buying some more parts. Managed to find some facebook bargains for wheels and tyres. found some Rota force 17×7 wheels on ebay for £100. Arouns 50 miles away so set of to collect. They were in a bit of a state but managed to clean them up with a flap wheel removing the corrosion. Also found a set of Bola b10 in 17×7.5. These would work well for the semi slicks with the Rotas being used for the wets. Purchased some used Uniroyal rainsports in 215/45/17 and some cooper rs3r in 225/45/17. Perfect fitment for the wheels I had purchased and stupidly cheap in comparison to a new set.

It was now time to move onto the rear end. Ordered some used r56 arms from ebay for £60 for the pair. Fitted new bearings and cleaned them all up etc. Purchased some R56 bolts for the arms etc and new drop links. Purchased some maxspeeding rods rear adjustible arms. Quality seems decent, paid £38 per set so just over £70 for the 4. Kept the r53 rear subframe and mounted all the new parts to it. Purchased new bushes for the rear swing arms as everybody said not to poly these due to them putting to much pressure on the top mounts. While we were in this area we cut the battery tray out as it would be in the way for the new exhaust when its made. Also purchased some 280mm disks paired with r56 JCW rear calipers, PBS pads and braided HEL lines. New abs sensors and replaced every bolt, paired with a whiteline ARB. Also mounted the rear shocks, using Driftworks adaptors to allow adjustment inside the car but cutting a samll hole. The adaptor simply just bolts onto the top of the adjuster. The adjuster for the coilovers are at the top on the minis so unfortunately the only way to adjust is to remove them each time. Anways have some more photos!!

I decided at this point after speaking with a few of the turbo guys, that I wanted more control over what I could monitor form the stock ECU. I also was told that there were limitations with the stock ECU and map reading. I went ahead and ordered a ECU master EMU black pnp mini r53 unit. The ECU is a direct replacement for the stock ecu and comes with a pre loaded map so the car will start. I also ordered a v3 rkde unit with oil pressure, temp, AFR and lamda sensor, Mac valve to control boost along with a bluetooth adaptor so I can run a digital dash.

So after this point the budget had well and truely taken a hammering. I decided the only real thing so far letting down the build was the DIY manifold we made. So I reached out to Walton Motorsport and ordered a r53 turbo manifold. It arrived shortly after and I knew immediately id made the correct choice. The quality and fitment was amazing. I much prefer this to the sidewinder manifolds offered by other retailers. The placement of the flange for the turbo meant the downpipe was quite easy to make just looping round on a 180 then passing over the subframe.

Due to the turbo being internally gated it came with a standard size 5 stud t25 flange. I wanted everything on a V band to ensure that everything was gasketless and easily removable if the need ever arose. I purchased and adaptor from Bartek which was horrendous. It did not fit, they advised grinding it down to make it fit, which made it no better. This was sent back for a refund and another bought from mamba turbos I believe which is a much better quality item, so the t25 to 3″ v band was now complete. This was mounted to the turbo with a gasket and stud and nut kit with VAG copper bolts and washers. I also installed a stud and nut kit on the head for ease of fitment and or removal at a later date. These are parts from the 1.8t VAG engine which include studs for the exhaust head side, copper nuts and washers. These work very well and dont come loose due to the different material types.